Electric drive system

According to the composition and arrangement of electric drive system, electric vehicles can be divided into four types: mechanical transmission type, non-variable transmission type, non-differential type and electric wheel type.

1. Pure electric vehicles with mechanical transmission. It was developed from a petrol-powered car with the front and rear wheels of the engine, retaining the transmission system of an internal-combustion engine car, only replacing the internal-combustion engine with an electric motor. This structure can improve the starting torque of pure electric vehicles and reserve power at low speed.

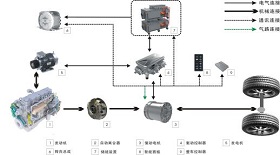

2. Non-variable speed electric vehicle. The main feature of this drive system is to remove the clutch and the transmission, adopting the fixed speed ratio reducer through the motor control to achieve the variable speed function. The advantage of this structure is that the mass of the transmission device of the mechanism is relatively light and the volume is small, but the requirements for the motor are relatively high, which requires not only a high starting torque, but also a large reserve power, so as to guarantee the starting, climbing and accelerating power performance of the pure electric vehicle.

A pure electric vehicle has other structure without gearshift.The structure is similar to the arrangement of a fuel vehicle with a horizontal front and front wheel drive. It integrates the motor, fixed speed ratio reducer and differential into a whole, with two half-shafts connected to drive wheels. This structure is common in small electric vehicles.

3. Non-differential electric vehicle. This structure adopts two motors, which drives two wheels separately through the fixed speed ratio reducer. The speed of each motor can be adjusted independently. When the vehicle turns, the electronic control system realizes the electronic difference speed. Therefore, the motor control system is more complex.

4. Electric wheel type pure electric vehicle. The motor is installed directly in the driving wheel (also known as hub motor), which can further shorten the power transmission path between the motor and the driving wheel. This structure requires high control accuracy and reliability of the control system.